ISO 13485 compliance using DelmiaWorks

As someone who defended various QMS’s (Quality Management Systems) in more than 70 audits over 14 years, it is no surprise that I am such a huge fan of DelmiaWorks Quality Modules. Below are some examples of how compliance with ISO 13485:2016 can be met using DelmiaWorks.

A typical ISO 13485/9001 audit at a plant backed by DelmiaWorks will have the following breakdown: 30% of the auditors' time is spent on the production floor and 70% of the auditors' time is spent going through the different DelmiaWorks modules and reviewing procedures, quality records, and other objective evidence of the Quality Management System.

Below, I have copied sections of the ISO 13485:2016 with the relevant section highlighted in yellow. Examples of the DelmiaWorks modules that meet the standard requirements are presented as well. Please pay special attention to the ‘Additional tips’ section.

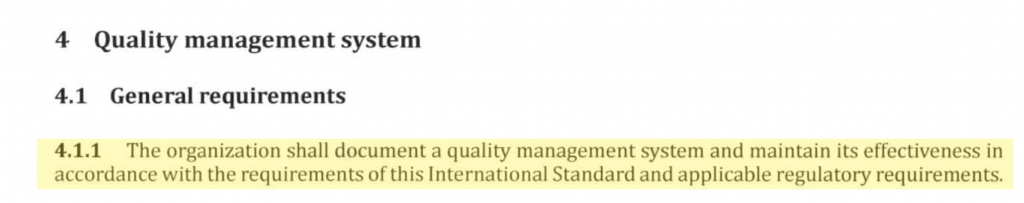

4.1.1 Document the Quality Management System (QMS)

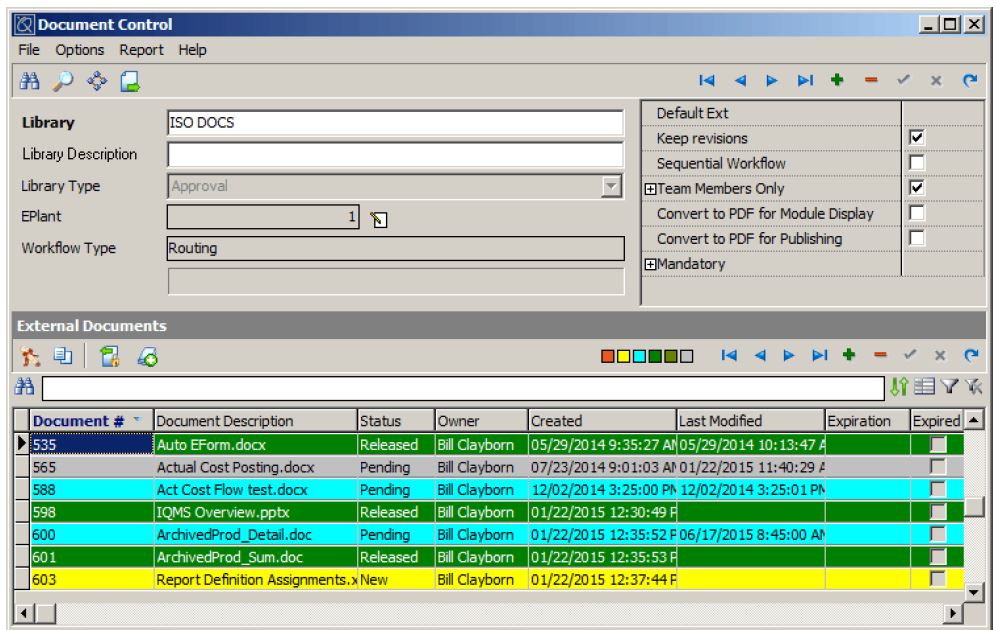

The Doc Control module meets this requirement by documenting and tracking the different revisions of QMS documentation required by ISO 13485/9001:

The Doc Control module meets this requirement by documenting and tracking the different revisions of QMS documentation required by ISO 13485/9001:

- Quality Policy

- Quality Objectives

- Quality Manual

- Procedures

- Customer files

- Any other documents that your organization requires in order to manage its business.

Proving compliance to ‘effectiveness of the Quality Management System’ can be a bit more tricky.

Proving compliance to ‘effectiveness of the Quality Management System’ can be a bit more tricky.

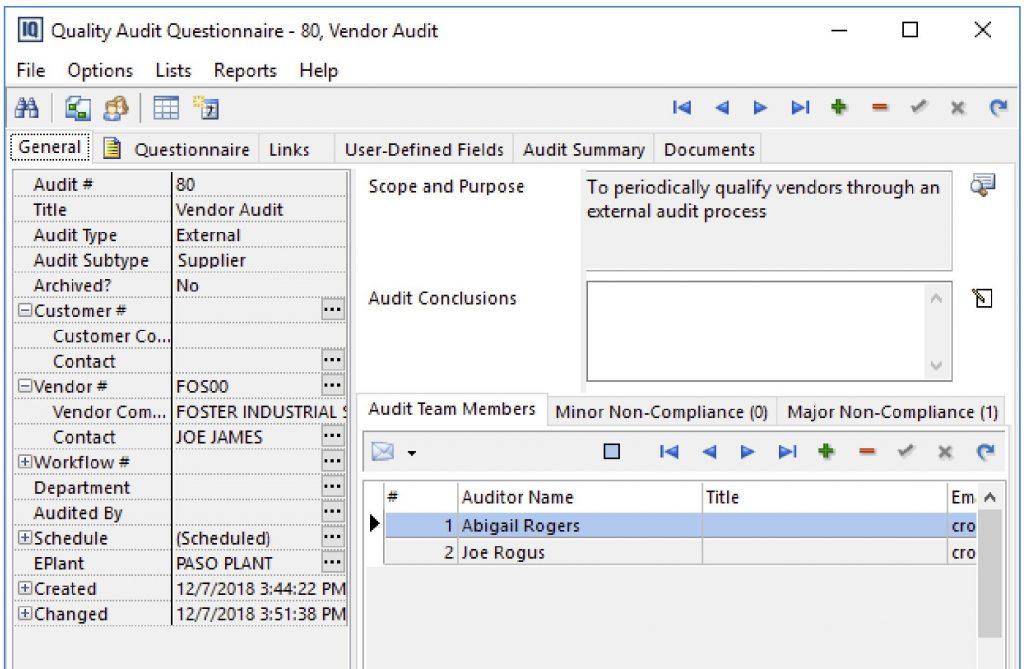

This is where DelmiaWorks Quality Audit module comes into play. Audit results are a great way to gage the effectiveness of a QMS. Use the Quality Audit module to track

- Customer audits

- Supplier audits

- Regulatory audits

This module encompasses audit scope, observations, findings, and how the findings were addressed. This is a one-stop shop that takes a lemon, an audit finding, and turns it into lemonade. When an auditor returns for a follow-up audit, you have a systematic method of showing, “We had this problem in one place, this is how we solved it, this is how we improved in additional places, and this is how we tracked it, so now we know that we are better”. Effectiveness of the QMS proven!

This module encompasses audit scope, observations, findings, and how the findings were addressed. This is a one-stop shop that takes a lemon, an audit finding, and turns it into lemonade. When an auditor returns for a follow-up audit, you have a systematic method of showing, “We had this problem in one place, this is how we solved it, this is how we improved in additional places, and this is how we tracked it, so now we know that we are better”. Effectiveness of the QMS proven!

Additional tips when complying with ISO 13485:2016 4.1.1

- Have upper management be the authorizer of the Quality Policy, Quality Objective and Quality Manual documents. This stands as objective evidence to upper management support and commitment.

- Only allow engineering and quality access to previous revisions of their respective documents. Make it so that all other users only have access to the latest revision. Auditors love to see that you have this flexibility and control.

4.1.2(b) Risk based approach

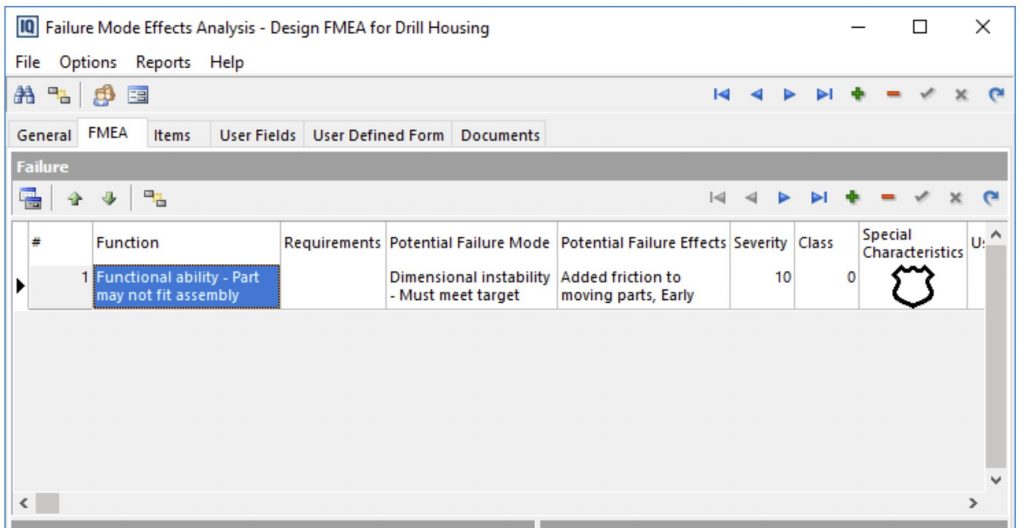

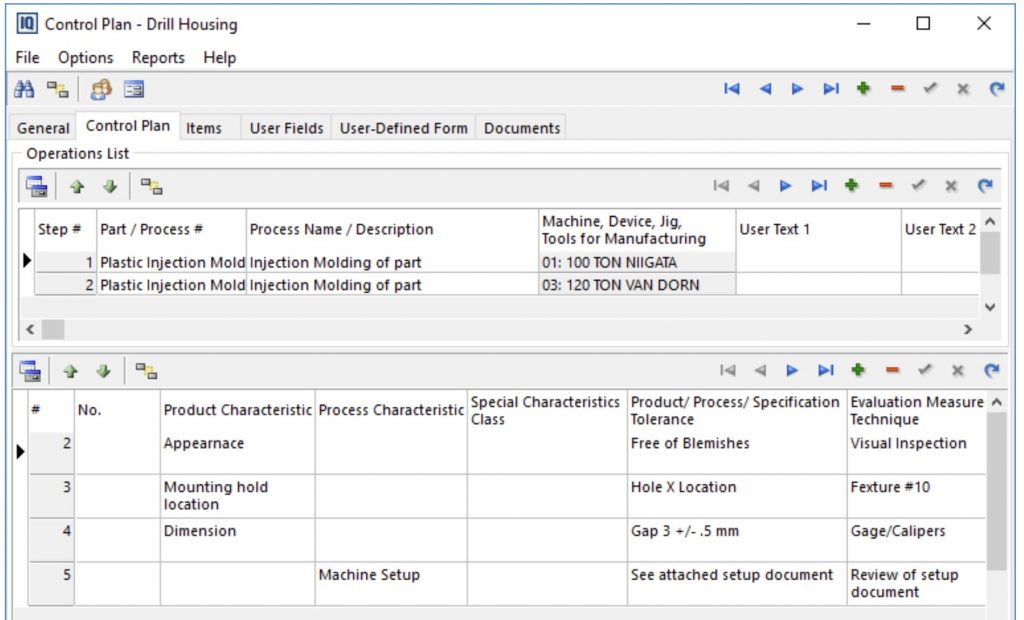

Apply a risk-based approach to the QMS using the FMEA and Control Plan modules. FMEAs and Control Plans are associated with manufactured and purchased items. While using Excel to maintain FMEAs and Control Plans is common for many companies, there is an advantage to creating and maintaining them in DelmiaWorks.

Apply a risk-based approach to the QMS using the FMEA and Control Plan modules. FMEAs and Control Plans are associated with manufactured and purchased items. While using Excel to maintain FMEAs and Control Plans is common for many companies, there is an advantage to creating and maintaining them in DelmiaWorks.

Associating FMEA/Control Plans with the manufactured or purchased items assures that engineering, quality, and production are all working off of the latest revision. As these are frequently updated documents, it is important that all stakeholders have access to the source.

Associating FMEA/Control Plans with the manufactured or purchased items assures that engineering, quality, and production are all working off of the latest revision. As these are frequently updated documents, it is important that all stakeholders have access to the source.

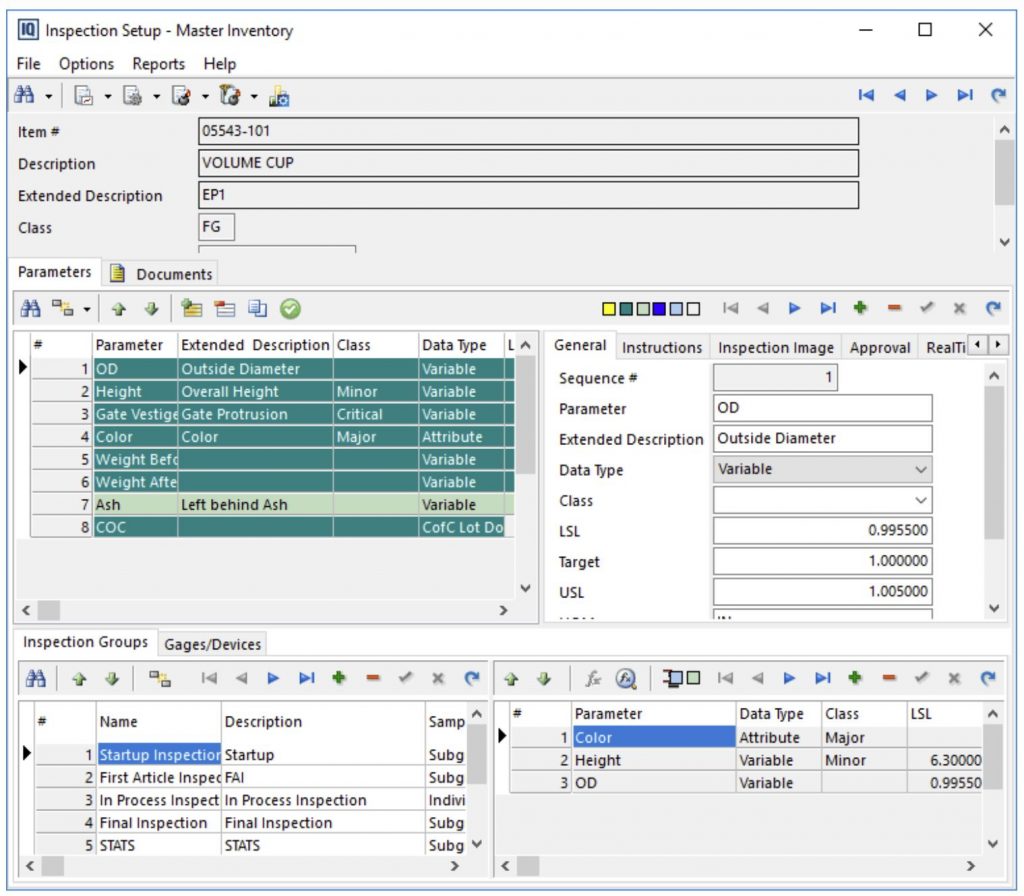

5.2 Customer Focus

The Inspection Setup module is a powerful quality tool. It provides the ability to customize the inspection of a production part at every level of production. It also enables the team to create custom inspections for raw material.

Specific inspection instructions, images, and approvals are available for each inspection item. Inspection records can be created in DelmiaWorks and are associated with inspection groups.

Additional tips when complying with ISO 13485:2016 5.2

Consider part or dimension specific GRR (Gage R&R) at both your location and your customer's before the start of production. This is especially important when tolerances are tight or dimensions are critical.

Cpk calculations (available in the SPC module) are a statistically sound method of ensuring you and your customer know your process capability.

6.1 (b) Provision of resources

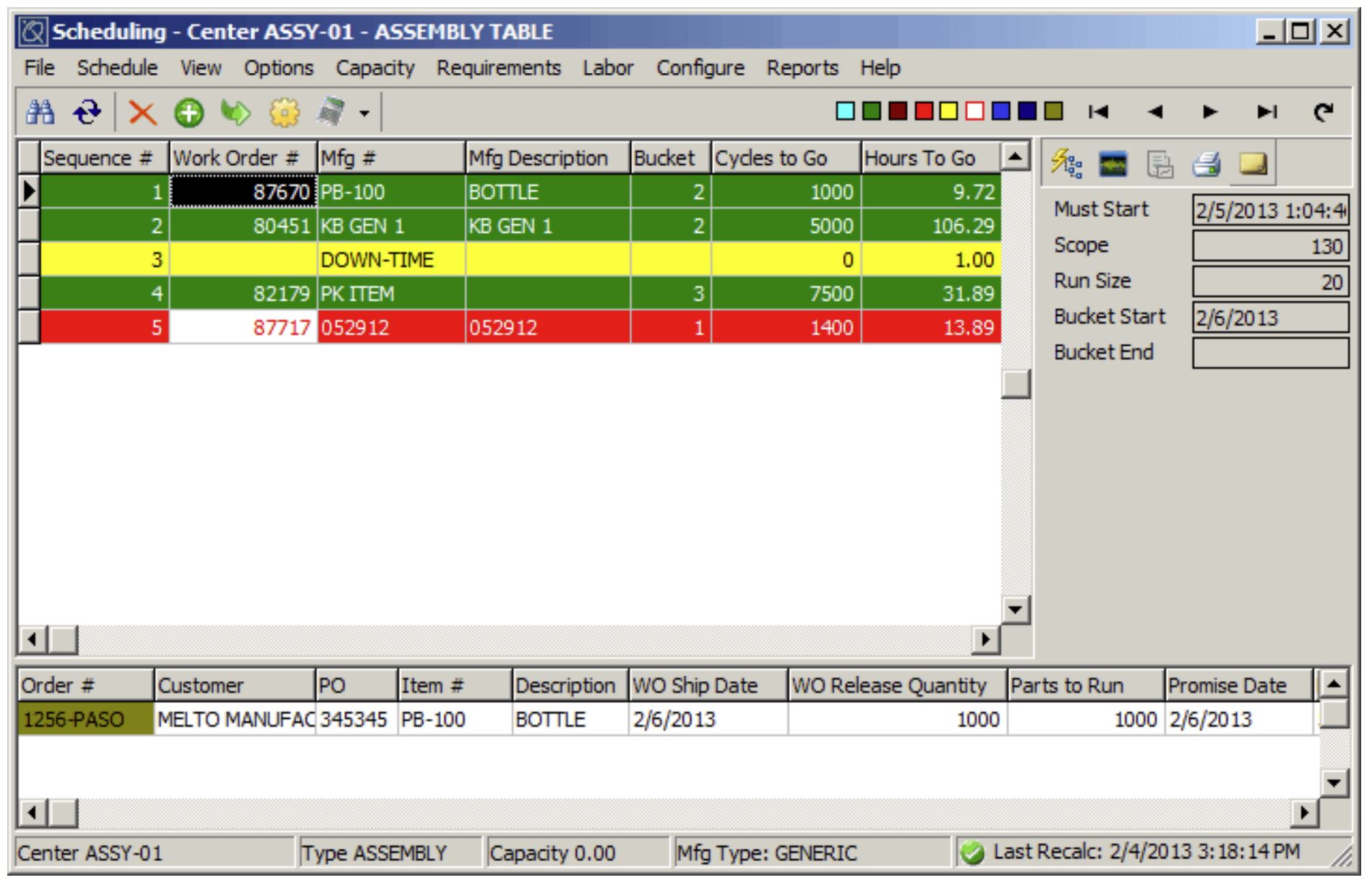

The ultimate management of resources in a manufacturing environment is determined by the scheduling of production work. Scheduling jobs and running the jobs in a timely manner is what assures customers will get their products on time.

Additional tips

The DelmiaWorks Finite Scheduling module is extremely powerful and will save the scheduler a lot of time as long as the BOM’s are accurate, parts on the sales orders have active BOM’s, inventory is managed correctly via DelmiaWorks, and the shop calendar is set to correctly reflect work center availability.